Plowman Craven supported Ballymore’s regeneration of the historic Bishopsgate Goodsyard by delivering safe, survey-grade insight into inaccessible Victorian infrastructure.

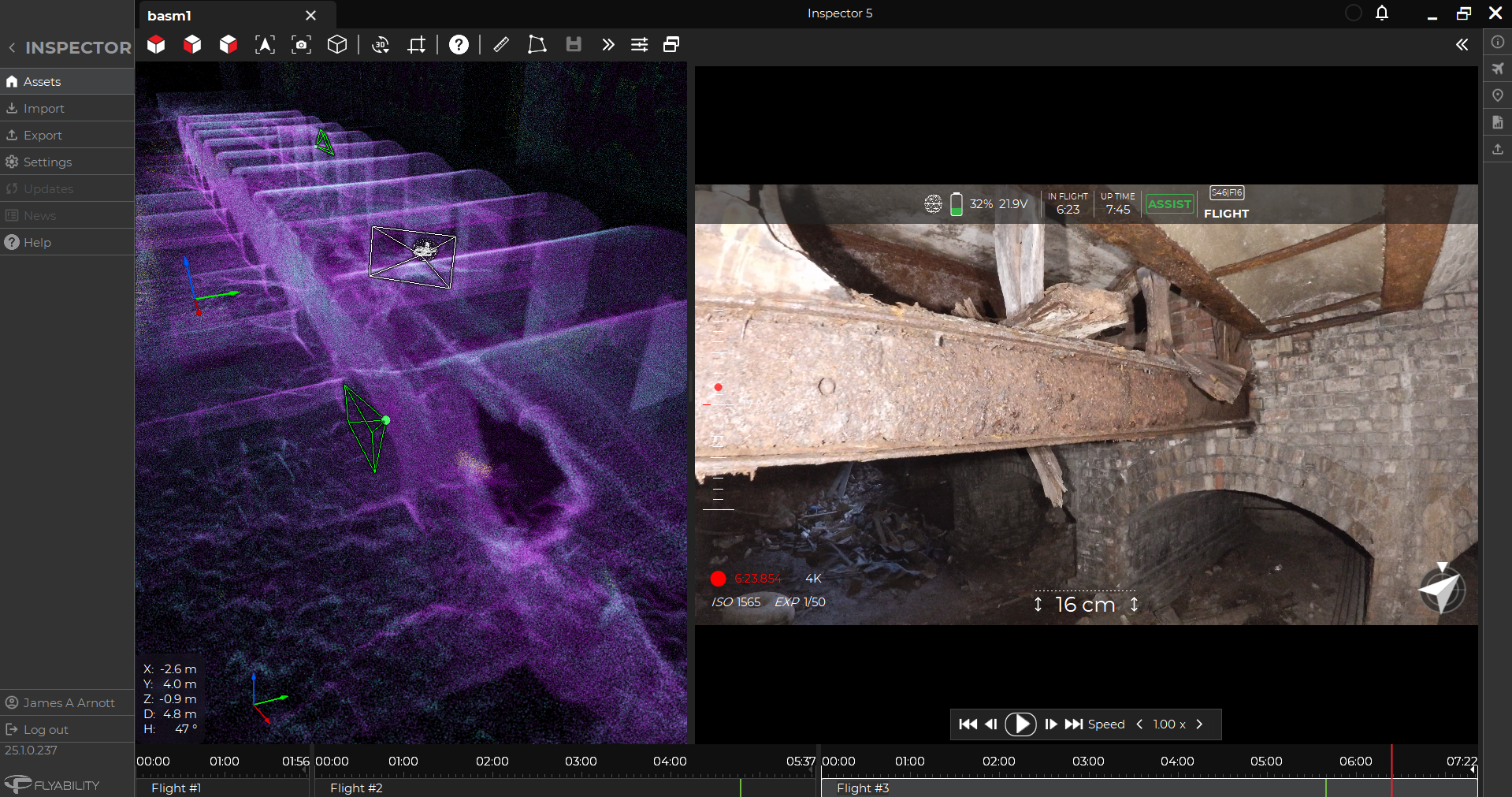

Conventional surveys were too hazardous due to confined spaces, structural instability, and health risks. Using a blend of traditional survey and advanced drone technology (Elios 3 with LiDAR), the team captured accurate dimensional and visual data to inform sustainable design and reuse.

Ballymore, a specialist in unlocking complex development opportunities across London’s built environment, approached Plowman Craven to support a critical phase of their Bishopsgate Goodsyard regeneration scheme.

Set in the heart of Shoreditch, this vast and iconic site includes a mix of elevated and subterranean Victorian infrastructure.

As part of a wider push to upcycle existing assets rather than demolish and rebuild, Ballymore required a detailed understanding of existing spatial stock to inform reuse, redesign, and reinforcement strategies.

The aim was to retain and enhance heritage structures wherever viable – a move aligned with growing pressure in London to reduce embodied carbon, limit disruption, and bring under-utilised space back into productive use.

Ballymore’s vision to breathe new life into the Bishopsgate Goodsyard relied on accurate dimensional and visual data from several disused and partially buried structures which had delayed the project which had already spanned a number of years. These areas presented unique access and safety challenges meaning conventional survey was just too dangerous

A conventional survey approach would have required multiple personnel, temporary access works, and extended on-site presence – all of which posed unacceptable safety risks and inflated project costs.

To deliver both safety and survey-grade accuracy, Plowman Craven deployed a combined methodology:

Our team leveraged established internal protocols to:

The result: minimal site time, maximum insight, and zero risk to personnel.

By deploying the Elios 3, we eliminated the need for human entry into hazardous and unstable environments. This dramatically reduced exposure to hazards and eliminated the need for scaffolding, gas detection, or rescue plans.

Our team didn’t just inspect – we captured accurate, geo-referenced LiDAR data, enabling Ballymore’s architects and engineers to incorporate underground voids into structural modelling with confidence.

This project exemplified how high-resolution data can support upcycling: retaining historic fabric, reducing embodied carbon, and preserving character – all while enabling modern functionality.

Single-team deployment and minimal access preparation significantly reduced site time and cost. What would typically require a multi-person confined space team was completed in a fraction of the time with no compromise on safety or accuracy.

With integrated 3D data from above and below ground, Ballymore gained the complete picture required to plan their rejuvenation works – supporting confident decision-making without guesswork.

“Plowman Craven’s approach allowed us to rethink what was possible at Bishopsgate Goods Yard. Their ability to safely capture data from complex and previously inaccessible areas was instrumental in supporting our upcycling strategy. It’s enabled us to move forward with a clearer understanding of what we can retain and enhance.”

The Bishopsgate Goodsyard project is a prime example of how digitally enabled inspection and survey can empower sustainable urban regeneration.

Through a smart combination of traditional survey methods and next-generation confined space technology, Plowman Craven helped Ballymore assess and unlock hidden potential in one of London’s most ambitious upcycling schemes.

By turning previously inaccessible voids into understood, usable, and design-integrated spaces, we didn’t just map structures – we enabled smarter reuse of the urban fabric.