Ensuring structural safety, compliance and performance through precise digital inspection.

Delivering data-driven insight for safer, compliant and longer-lasting assets. From bridges and tunnels to façades, industrial plants and utilities networks, understanding how structures perform is key to maintaining safety, reliability and asset value.

Plowman Craven combines advanced imaging, robotics and digital modelling to deliver accurate, non-intrusive inspection and reporting.

Our integrated approach provides asset owners with the clarity to act early, manage risk and extend the life of critical infrastructure.

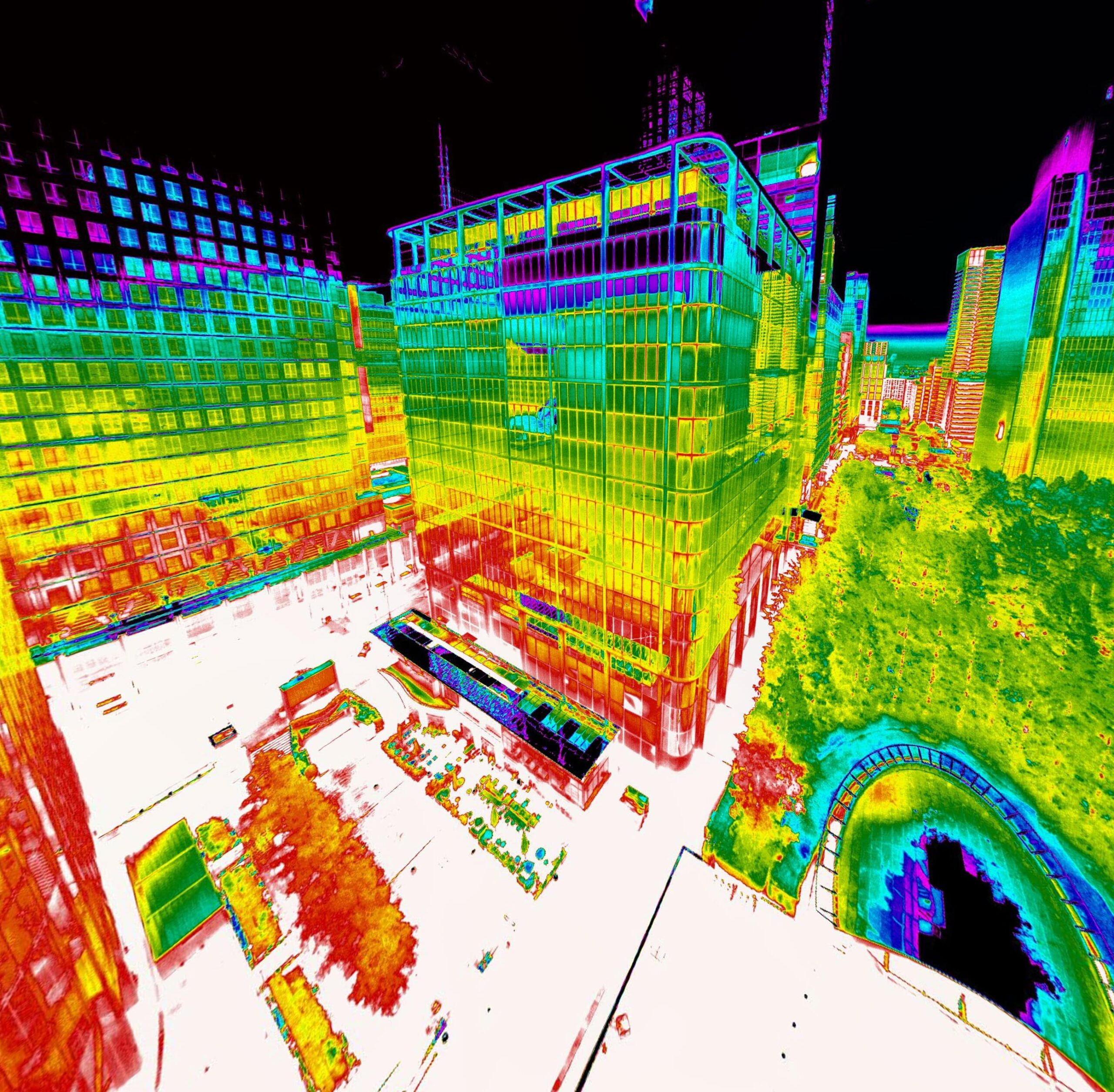

Our Condition Assessment service establishes a detailed understanding of an asset’s condition, both inside and out. Using visual, thermal and structural inspection techniques, we provide measurable insight that supports proactive maintenance, compliance and investment decisions.

Our robotic and crawler-based inspections deliver detailed visualisation of internal and confined spaces without disruption. These non-intrusive methods improve safety, minimise downtime and provide a clear view of defects that traditional inspections can’t reach.

We integrate inspection data into dynamic 3D models to create visual digital twins that track asset condition and performance over time. This enables interactive exploration, collaborative decision making and data-driven asset management.

Plowman Craven combines decades of measurement expertise with innovation in robotics and digital engineering. Our Asset Integrity and Condition services transform inspection into actionable intelligence that supports confident, compliant and sustainable asset management.