Delivering a safe, high-resolution structural inspection of a live urban rail bridge using remotely piloted UAS technology, eliminating the need for scaffold, rope access or over-water working.

Plowman Craven was commissioned to support the condition assessment of a operational rail bridge located within a dense urban setting. The bridge crosses a busy river used by regular vessel traffic and sits close to public areas, meaning traditional access-led inspections would be costly, disruptive and higher risk.

The brief was to capture clear, reliable inspection imagery across critical structural elements while maintaining normal rail operations and avoiding unnecessary public interface.

The inspection needed to address a number of practical and safety challenges:

A traditional inspection approach would have required extensive planning, temporary works and physical access, increasing both programme risk and safety exposure.

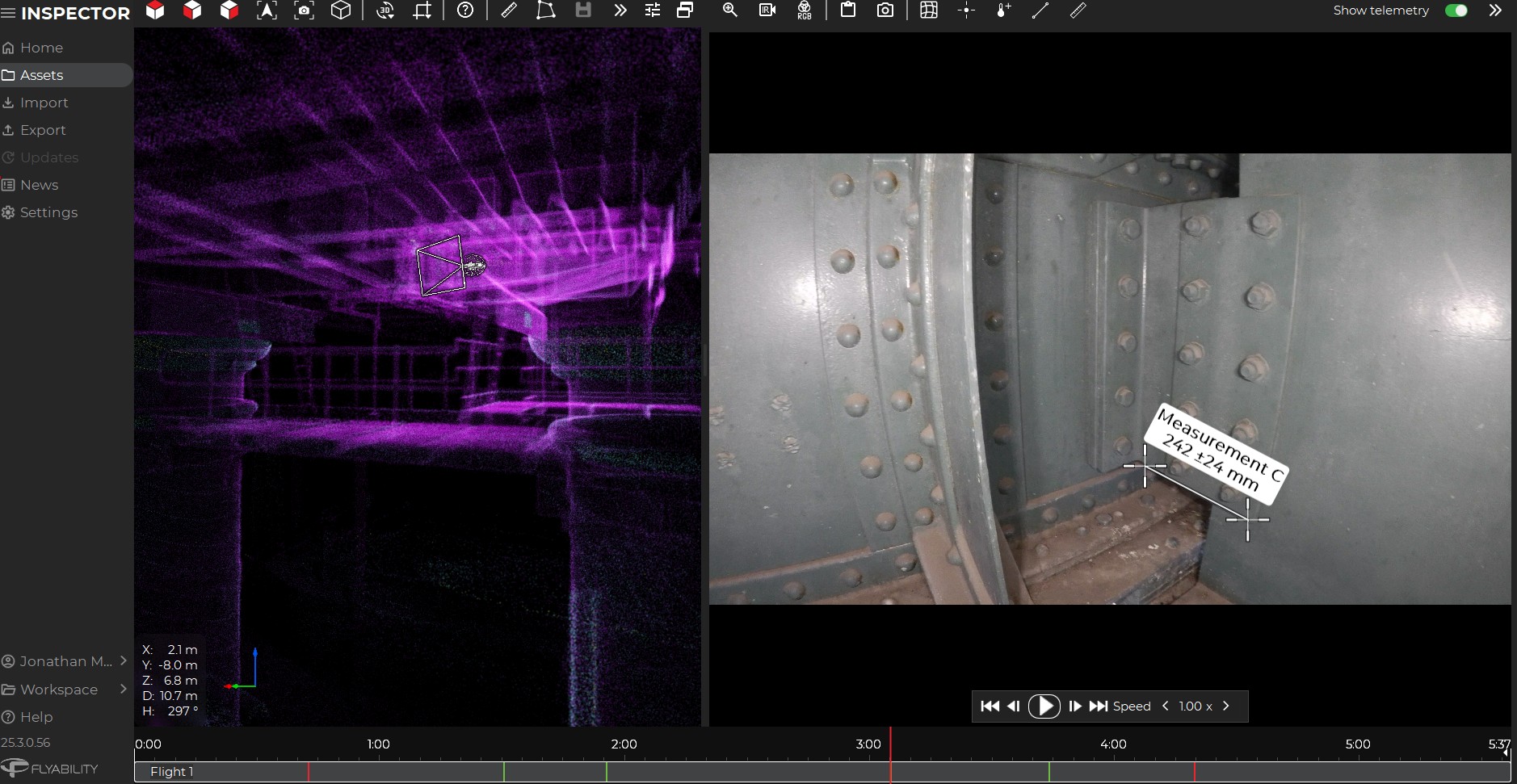

Plowman Craven delivered a fully remote inspection using close-range UAS technology, replacing physical access systems with a controlled, software-led inspection workflow.

A confined-space capable inspection drone was deployed to fly in close proximity to the bridge structure, enabling detailed visual inspection of underside and hard-to-reach elements without scaffold, MEWPs or rope access. All operations were planned and delivered within approved RAMS and aviation controls suitable for a complex urban environment.

The inspection approach combined capture and digital review in a single, integrated solution:

This approach removed the need for repeated site access while providing engineers with a clear, auditable inspection record.

The remote UAS-led inspection approach delivered clear safety, programme and operational advantages compared to traditional access-led inspection methods.

Remote inspection eliminated the need for working at height and significantly reduced exposure to high-risk environments.

The inspection was delivered without scaffold, road closures or temporary access systems, allowing rail and surrounding activity to continue as normal.

Close-range imagery provided enhanced visibility of structural details compared to traditional visual inspections, supporting more informed condition assessment.

Rapid deployment and demobilisation shortened inspection timeframes and reduced programme impact.

Digital inspection outputs created a repeatable baseline, enabling easier comparison and planning for future inspections.

This project demonstrates how remote UAS inspection can replace access-heavy inspection methods on complex urban rail structures.

By combining drone-enabled capture with an interactive digital inspection environment, Plowman Craven delivered a safer, more efficient inspection while improving the quality and usability of the data. The outcome supports better-informed asset management decisions and shows how UAS technology can be confidently used as a primary inspection tool in constrained, live environments.