Turning inspection data into enduring digital insight.

Digital Asset Intelligence transforms inspection outputs into structured, intelligent datasets that drive smarter asset management.

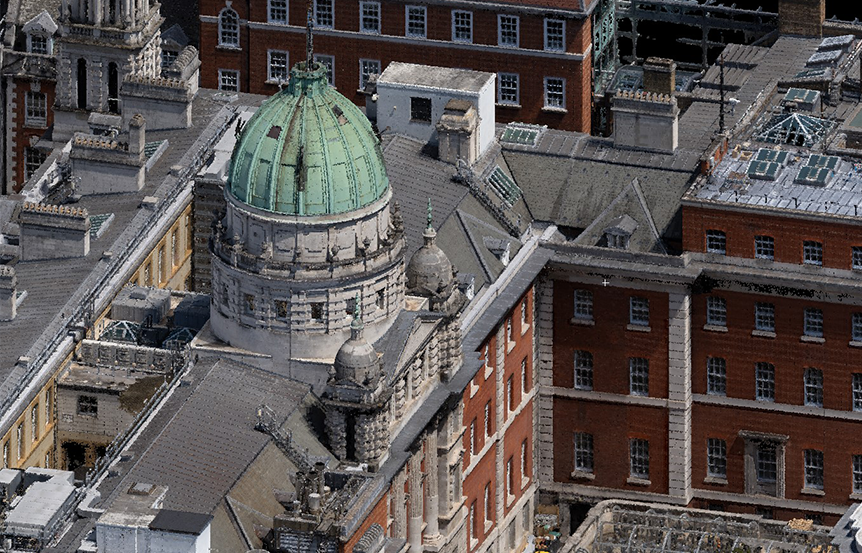

By combining high-definition LiDAR, visual and thermal data with advanced 3D modelling, we create accurate digital replicas of assets – the backbone for future digital twins.

Every inspection contributes to a living, scalable dataset that enables predictive maintenance, portfolio optimisation and long-term performance management.

Our process connects inspection data, visual context and analytics in one unified environment – providing the clarity needed to understand, manage and plan asset performance.

Combine inspection imagery, LiDAR point clouds and thermal data into accurate 3D models for a single, measurable view of your assets.

Embed defect information and performance data within the model to link asset condition directly to its physical location and hierarchy.

Compare repeat datasets over time to detect movement, deterioration or performance change, supporting predictive maintenance.

Aggregate insights across assets to identify risks, prioritise interventions and inform capital planning.

Host inspection-derived data securely in Easl by Plowman Craven. Visualise and share interactive 3D models within a collaborative environment that connects directly with BIM, O&M and FM systems.

Plowman Craven combines decades of spatial expertise with advanced inspection and data integration capabilities.

We bridge the gap between data capture and digital twin delivery, helping clients unlock the full value of their inspection data.